Back to Back Sales Order- Make Flow:

when ever we get order if we do not have on hand stock in warehouse we have three options to fulfill order.

1. Transfer from another warehouse

2. Buy from supplier

3.Start production in our manufacturing unit(Make).

Please watch and subscribe for few more topics in my youtube channel. Comment on below videos if you want any video on any fusion topics, i will try to make videos and share with you.

https://www.youtube.com/channel/UCmWV764laAtBcTb4uJXNk-Q/featured.

Create Sales order and scheduling

Make sure there is no stock in preferred warehouse

Verify that there is no available stock in the preferred inventory - DOOCSPS1

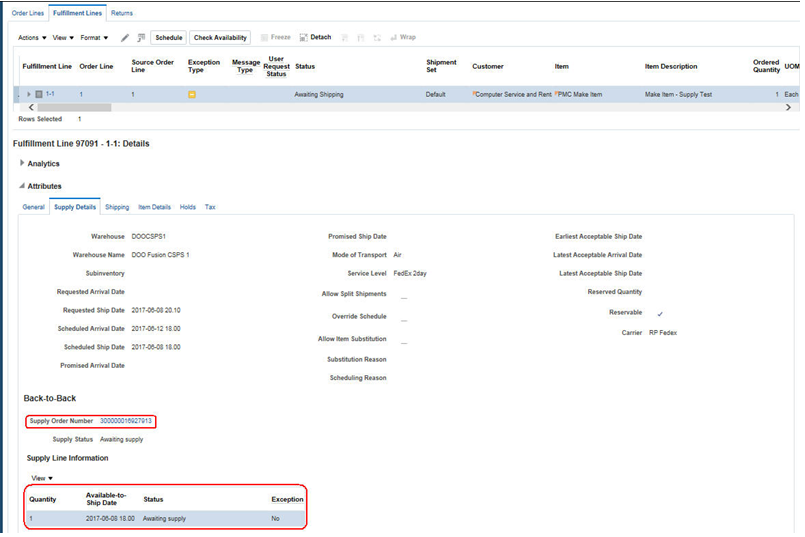

Review the Fulfillment Line on the Sales Order - this shows that the line is - Awaiting Shipping. The Supply Details shows no supply information

Supply Details Tab shows no information. Verify the Scheduling

details by selecting - Check Availability

Navigate to Actions - Availability Details - which shows that the item will be manufactured (make) in DOOCSPS1 and then Shipped from this inventory

Initiate the Supply Orchestration Process

Execute the Scheduled Process - Release Planning Recommendations

Review the outcome of running the Release Planning Recommendations

Refresh or requery the Sales Order - Fulfillment View

The supply order has been created, open the Supply Orchestration

order by clicking on the supply order number

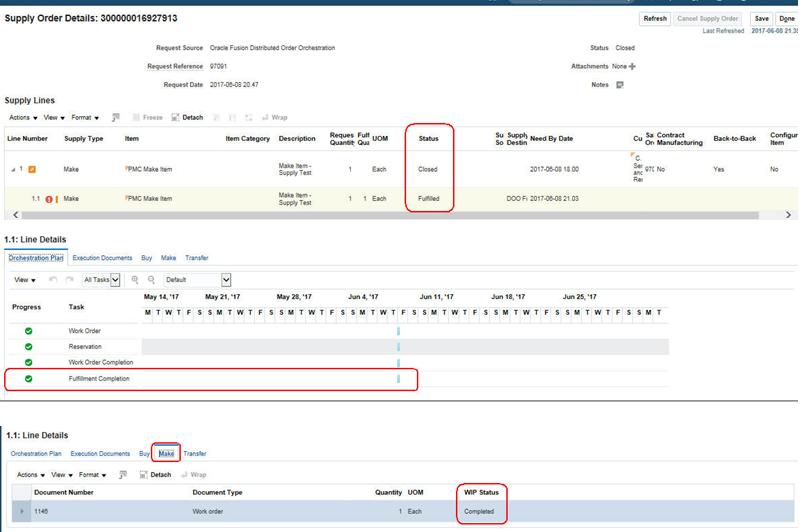

Click on the Orchestration Plan Tab to view the supply order

fulfillment plan.

Select the - Execution Documents and Make - Tabs - A work order

has been created

Navigate to - Manufacturing - Work Execution

Select task - Manage Work Orders

Search for the Work Order described in the supply order flow (in

this case 1146)

Note that the Work Order status is - Released

Complete the Manufacturing Process

Select task - Review Dispatch List

Search for and expand the Work Order (click on arrow)

Click - Quick Complete

Review the outcome of Manufacturing the Item.

Review the Supply Order which shows the status of the Work Order -

Work Order Complete

Review the Sales Order - Fulfillment Lines DetailsNOTE: that the Supply order information - on the Fulfillment Line shows - Goods unavailable

NOTE: This is a known issue that Support is working with

Development on this issue

NOTE: This will not prevent the process from completing

NOTE: This will not prevent the process from completing

Review the Supply Order - this shows an error - The supply line is

in exception because a date was changed in the execution document.

Review Inventory Item Availability, this shows that there is now -

On Hand - availability. No stock is available to be reserved as the newly

manufactured item is reserved against the original order.

Ship Items on the Sales Order

Create a Pick Wave

Confirm the Pick Slip

Ship Confirm the Shipment

Review the outcome of shipping the Sales Order

The Order line has been shipped and it is now Awaiting Billing

Inventory Item Availability shows that there is no on hand stock

The Supply Order is Closed

The supply details on the fulfillment line shows that the Supply Order is closed - Fulfillment Line status is Awaiting Billing

Invoice the Order

Review the outcome of invoicing the Sales Order

The Fulfillment Lines is Closed

No comments:

Post a Comment